The Bruno Joey Lift is a versatile mobility solution designed for safe and efficient transfers. Its installation ensures ease of use and reliability‚ making it a popular choice.

1.1 Overview of the Bruno Joey Lift

The Bruno Joey Lift is a portable‚ easy-to-use transfer device designed to assist individuals with mobility challenges. It offers a safe and dignified way to transfer users between surfaces like beds‚ chairs‚ or vehicles. Built with durability and simplicity‚ the lift features a compact design‚ making it ideal for home or clinical settings. Its intuitive controls and lightweight frame ensure ease of operation for caregivers. Recognized for its reliability‚ the Bruno Joey Lift is a trusted solution for enhancing independence and accessibility in daily life.

1.2 Importance of Proper Installation

Proper installation of the Bruno Joey Lift is crucial for ensuring safety‚ functionality‚ and longevity. A correct setup guarantees the lift operates smoothly‚ reducing the risk of mechanical failure. It also ensures compliance with safety standards and manufacturer guidelines‚ which are essential for user protection. Improper installation can lead to instability‚ safety hazards‚ or equipment damage. By following installation instructions carefully‚ you can maximize the lift’s performance and provide a reliable solution for mobility assistance. Proper installation is the foundation for safe and effective use of the Bruno Joey Lift.

Pre-Installation Requirements

Pre-installation involves gathering tools and materials‚ assessing the site for compatibility‚ and taking precise measurements to ensure proper fit and safe operation of the Bruno Joey Lift.

2.1 Tools and Materials Needed

Installing the Bruno Joey Lift requires specific tools and materials to ensure a secure and proper setup. Essential tools include a power drill‚ screwdrivers‚ wrenches‚ and a measuring tape. Materials needed are screws‚ bolts‚ washers‚ and a power supply cord. Additionally‚ a level and concrete anchors are necessary for floor securing. Ensure all components are included in the installation kit and refer to the manual for any specific requirements. Proper preparation of these items guarantees a smooth and safe installation process for the Bruno Joey Lift.

2.2 Site Preparation and Measurements

Proper site preparation and accurate measurements are critical for a safe and functional Bruno Joey Lift installation. Ensure the installation area is clear of obstacles and level. Measure the floor space to confirm it aligns with the lift’s dimensions. Use a tape measure to mark the anchor points precisely‚ ensuring they match the manufacturer’s specifications. Double-check all measurements to avoid errors. Verify the weight capacity and ensure the floor can support the lift. Proper preparation guarantees a secure and reliable installation‚ adhering to safety and functionality standards.

Understanding the Components

Familiarizing yourself with the Bruno Joey Lift’s components is essential for successful installation. Key parts include the lift frame‚ control panel‚ and safety mechanisms‚ ensuring smooth operation and safety;

3.1 Unpacking and Inventory of Parts

Begin by carefully unpacking the Bruno Joey Lift shipment to ensure all components are included and undamaged. Lay out the parts‚ such as the lift frame‚ control panel‚ and mounting hardware‚ in an organized manner. Refer to the installation manual to identify and cross-reference each item. This step is crucial to confirm that no parts are missing or damaged‚ which could delay the installation process. A thorough inventory ensures a smooth and efficient setup of the lift system.

3.2 Identifying Key Components and Their Functions

The Bruno Joey Lift consists of essential components designed for optimal functionality. The lift frame provides structural support‚ while the control panel manages operations. The power supply ensures reliable energy delivery. Other critical parts include the lifting arm‚ which handles the transfer‚ and safety sensors that prevent accidents. Understanding each component’s role is vital for proper installation and operation. Familiarize yourself with these elements to ensure all functions work seamlessly together‚ providing safe and efficient transfers for users.

Safety Precautions and Guidelines

Always wear protective gear during installation. Ensure the area is clear of obstacles. Follow manufacturer instructions precisely to avoid accidents. Test the lift thoroughly after installation.

4.1 General Safety Tips

Always wear safety gear‚ including gloves and safety glasses‚ during installation. Ensure the installation area is clear of obstacles and well-lit. Follow the manufacturer’s instructions meticulously to prevent accidents. Regularly inspect the lift’s components for damage or wear. Never exceed the lift’s weight capacity. Test the lift thoroughly before its first use. Keep loose clothing and long hair tied back. Ensure the floor is level and secure before proceeding. Maintain a clean workspace to avoid slips or trips. Adhere to all local safety regulations and guidelines.

4.2 Specific Warnings and Cautions

Never overload the lift beyond its specified weight capacity‚ as this can lead to mechanical failure. Avoid using the lift near water or in damp environments to prevent electrical hazards. Ensure the lift is securely anchored to the floor to prevent tipping or instability. Do not modify or tamper with the lift’s components‚ as this may void the warranty and compromise safety. Always disconnect the power supply before performing maintenance. Keep children and unauthorized individuals away from the lift during installation and operation. Failure to follow these warnings can result in serious injury or damage.

Step-by-Step Installation Process

The Bruno Joey Lift installation involves assembling components‚ securing the base‚ and connecting electrical systems. Follow the manual for proper alignment and torque specifications. Ensure all bolts are tightened evenly. Test the lift’s operation before first use. Always refer to the manufacturer’s instructions for precise guidance. Proper installation ensures safety and optimal performance. Double-check all connections and mechanisms to avoid malfunctions. If unsure‚ consult a professional. Adhere to safety protocols throughout the process to guarantee reliability and user safety.

5.1 Securing the Lift to the Floor

Securing the Bruno Joey Lift to the floor is critical for stability and safety. Begin by positioning the lift on a level‚ sturdy surface. Use concrete anchors to ensure a solid connection. Drill into the floor according to the manufacturer’s specifications‚ then tighten the bolts evenly. Double-check the lift’s alignment and plumb to prevent uneven installation. Refer to the manual for torque specifications. Once secured‚ test the lift’s stability by gently rocking it. If any movement is detected‚ recheck and tighten the anchors as needed. A proper installation ensures reliable operation and user safety.

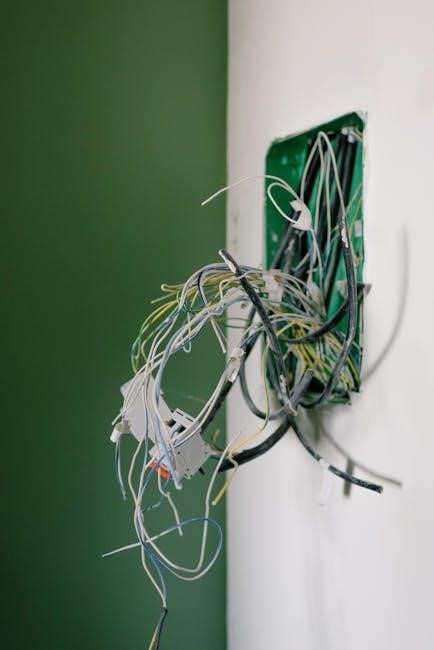

5.2 Installing the Control Panel and Electronics

Install the control panel by mounting it at a user-friendly height‚ typically between 30-40 inches from the floor. Connect the electrical components securely‚ ensuring all wires are properly routed and insulated. Follow the wiring diagram in the manual to avoid mismatches. Use zip ties to organize cables neatly. Plug in the power supply and test the control panel’s functionality. Perform a systems check to ensure all buttons and sensors operate correctly. Finally‚ verify that all safety features are active‚ such as emergency stops and overload alarms‚ before final testing.

5.3 Connecting the Lift to Power Supply

Connect the Bruno Joey Lift to a dedicated 20-amp‚ 120-volt power supply. Ensure the circuit is properly grounded and meets local electrical codes. Turn off the power at the circuit breaker before connecting. Use the provided wiring harness to link the lift’s electrical components to the power source. Double-check all connections for tightness and insulation. Test the circuit with a multimeter to confirm voltage and polarity. Once verified‚ restore power and perform a safety test to ensure all systems function correctly before use.

5.4 Testing the Lift Before Use

Once installed‚ thoroughly test the Bruno Joey Lift to ensure safe operation. Begin by conducting a visual inspection of all components and connections. Perform a dry run without weight to check smooth movement and proper function of controls. Gradually test the lift with the maximum recommended weight to verify stability and performance. Check for any unusual noises‚ jerking motions‚ or malfunctions. Ensure all safety features‚ such as emergency stops and weight capacity limits‚ are functioning correctly. Only after successful testing should the lift be used for transferring individuals.

Common Mistakes to Avoid

Common errors include improper alignment of components and ignoring weight capacity limits. These oversights can lead to safety hazards and equipment malfunction‚ ensuring precise installation is critical.

6.1 Improper Alignment of Components

One of the most critical mistakes during Bruno Joey Lift installation is misaligning components. This can lead to instability‚ safety risks‚ and equipment malfunction. To avoid this‚ ensure all parts are precisely aligned according to the manufacturer’s guidelines. Use the provided templates or alignment tools to verify proper positioning. Double-check every connection before securing them permanently. Misalignment can cause uneven weight distribution‚ potentially resulting in accidents or damage to the lift. Always refer to the installation manual for specific alignment instructions and consider seeking professional help if unsure.

6.2 Ignoring Weight Capacity Limits

Ignoring the weight capacity limits of the Bruno Joey Lift is a dangerous oversight. Exceeding the specified weight can lead to structural failure‚ safety hazards‚ and potential injury. Always verify the maximum weight capacity in the manual and ensure the lift is not overloaded. Excessive weight can compromise the lift’s stability and longevity. Additionally‚ overloading may void the warranty and pose legal risks. Always adhere to the manufacturer’s guidelines to ensure safe and reliable operation. Conduct a test run after installation to confirm compliance with weight limits.

Troubleshooting Common Issues

This section addresses common issues during Bruno Joey Lift operation. Troubleshooting involves identifying electrical or mechanical problems and applying solutions. Consult professionals if issues persist.

7.1 Diagnosing Electrical Problems

Diagnosing electrical issues in the Bruno Joey Lift involves checking the power supply‚ control panel‚ and wiring connections. Ensure the lift is properly grounded and all circuits are intact. If the lift doesn’t power on‚ verify the circuit breaker or fuse. Check for loose or damaged wires and connectors. Use a multimeter to test voltage at key points. If issues persist‚ consult the manufacturer’s troubleshooting guide or contact a certified technician to resolve the problem efficiently. Electrical faults can often be resolved with basic diagnostic tools and attention to detail.

7.2 Resolving Mechanical Malfunctions

Resolving mechanical malfunctions in the Bruno Joey Lift involves inspecting moving parts for wear or misalignment. Lubricate hinges and joints regularly to ensure smooth operation. Check for loose bolts or screws and tighten as needed. If the lift jerks or binds‚ adjust the track alignment. Replace worn or damaged components promptly to prevent further issues; Always refer to the manufacturer’s guidelines for specific mechanical repairs. If unsure‚ consult a professional technician to ensure safety and proper functionality of the lift.

Maintenance and Upkeep

Regular cleaning and lubrication of moving parts ensure smooth operation. Follow the manufacturer’s guidelines for maintenance schedules and consider periodic professional inspections for optimal performance.

8.1 Regular Cleaning and Lubrication

Regular cleaning and lubrication are essential for maintaining the Bruno Joey Lift’s performance. Inspect and remove debris from all moving parts to ensure smooth operation. Use mild detergents to wipe down surfaces‚ avoiding harsh chemicals that may damage components. Lubricate hinges‚ rollers‚ and joints with silicone-based spray every 3-6 months. Check for wear on pivot points and re-lubricate as needed. Proper maintenance prevents corrosion‚ reduces friction‚ and extends the lift’s lifespan. Always refer to the manufacturer’s guidelines for specific recommendations.

8.2 Scheduling Professional Inspections

Regular professional inspections are crucial to ensure the Bruno Joey Lift operates safely and efficiently. Schedule inspections annually or every 500 cycles‚ whichever comes first. A certified technician will assess wear and tear‚ check electrical components‚ and verify proper alignment. They will also test safety features and address any potential issues before they become major problems. Neglecting professional inspections can lead to safety hazards or equipment failure. Always adhere to the manufacturer’s recommended inspection schedule to maintain warranty validity and ensure reliable performance. Regular check-ups are key to extending the lift’s lifespan.

Proper installation and maintenance ensure the Bruno Joey Lift operates safely and reliably. Always follow instructions and seek professional help for complex tasks to guarantee optimal performance and longevity.

9.1 Final Check and Safety Verification

A thorough final inspection ensures all components are secure and functioning correctly. Check the control panel‚ emergency stop‚ and weight limits. Test the lift with varying loads to confirm smooth operation. Verify proper alignment and stability to prevent accidents. Review the user manual to ensure compliance with safety guidelines. Clear the area of obstacles and ensure proper visibility. Conduct a final test run under supervision before first use. Schedule a professional inspection to validate installation integrity and safety standards. This step guarantees optimal performance and user safety.

9.2 Tips for Optimal Performance

Regularly clean and lubricate moving parts to maintain smooth operation. Adhere to weight capacity limits to prevent strain on the lift. Schedule periodic professional inspections to address wear and tear. Always follow the manufacturer’s guidelines for maintenance and repairs. Train users on proper operation techniques to avoid misuse. Ensure the lift is stored correctly when not in use to protect against damage. Perform routine tests on safety features like emergency stops and alarms. Keep the control panel free from obstructions for easy access. By following these tips‚ the Bruno Joey Lift will deliver reliable‚ long-term performance.

Additional Resources

Visit the Bruno Joey Lift manufacturer’s website for official manuals‚ guides‚ and technical support. Explore online forums and communities for user experiences and troubleshooting tips.

10.1 Manufacturer’s Support and Manuals

The Bruno Joey Lift manufacturer provides comprehensive support‚ including detailed installation manuals‚ troubleshooting guides‚ and technical specifications. These resources ensure a smooth setup process. Access them online or through customer service for expert assistance. Additionally‚ video tutorials and FAQs are available to address common questions and installation challenges. Regular updates and revisions are made to keep the information current and relevant for optimal performance and safety.

10.2 Online Communities and Forums

Online communities and forums offer valuable insights and peer support for Bruno Joey Lift installation. Platforms like Reddit or specialized mobility forums connect users‚ allowing them to share experiences‚ tips‚ and solutions. These spaces often include troubleshooting advice‚ installation tips‚ and real-world feedback from experienced users. Engaging with these communities can provide additional guidance and reassurance‚ helping you navigate the installation process with confidence and address any challenges effectively.